Waste Heat Recovery - Kohler Company

Kohler Company was looking for a way to recover the heat emitted from production in their Pottery facility. Kohler has four large kilns for pottery vitrification (turning clay to glass) with discharge stack temperatures above 800°F. Kohler Pottery conveniently has a large demand for lower temperature heat both for pottery drying and for domestic hot water generation. Kohler Pottery uses about the 18,000 gallons of 120°F hot water they utilize per day for production and for domestic purposes. In addition, Kohler uses a hot air at 250°F for their produce dryers.

The Kohler Pottery Heat Recovery project consisted of recovering high temperature heat from three shuttle kilns, and one tunnel kiln. The recovered heat was used as a heat source for five shuttle dryers and the domestic hot water system. The firing process in the shuttle kiln creates waste heat at a maximum temperature of 1,000°F at 65,000 pounds per hour. Total amount of heat recovery for a firing cycle on a shuttle kiln is 660,000 BTU’s. Additionally, Kohler’s Tunnel Kiln supplies the system with 1,540 MBH of heat constantly. Kohler’s tunnel kiln is rarely shut down as it takes 24 hours for a part to pass through the tunnel and shutdowns actually damage the kiln due to thermal expansion and contraction.

Customized Solution:

-

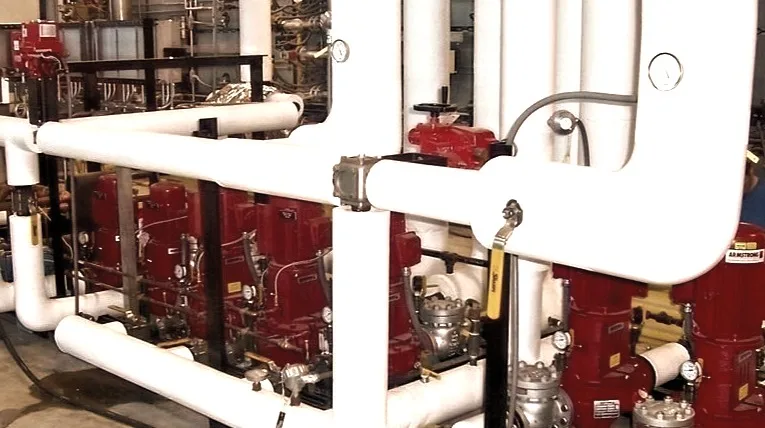

Using 3D modeling and FEA, the Rohde team designed a custom thermal storage tank capable of holding 4,000 gallons of water at 400 PSIG. Typical storage systems run to 125 PSIG. The pump skid was pre-piped and pre-wired in the Rohde shop to minimize disruption of plant operations. The pump skid included an Allen-Bradley PLC for control of the pumps and heat recovery system. A web-based Honeywell controller provides graphical user interface for operating and monitoring the PLC.

-

Enabled heat recovery of 254,000 therms per year; saving The Kohler Company $178,000 in natural gas costs within the first year. With 50% of the project cost funding provided by WI Focus on Energy, the payback period was only 2.5 years.

-

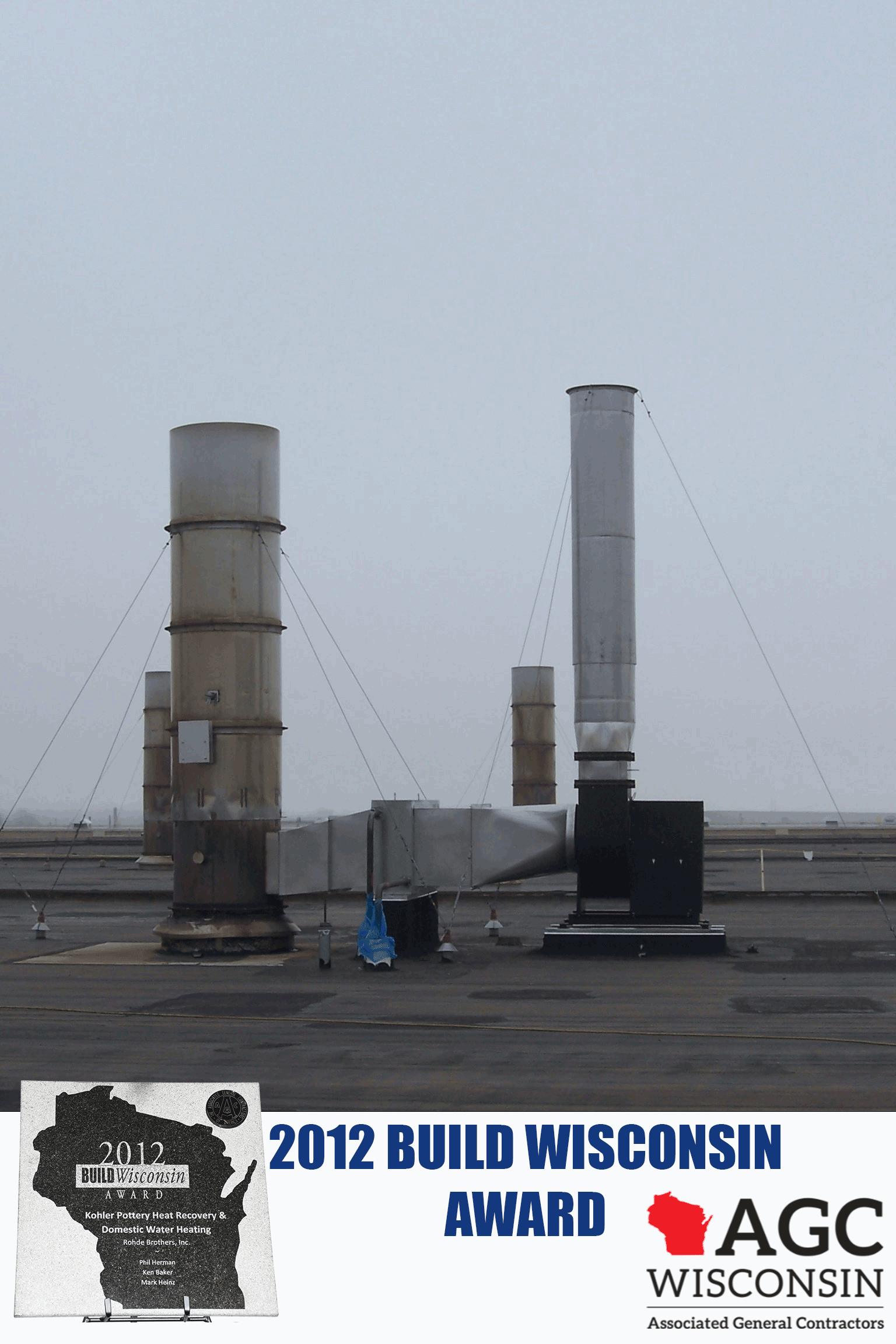

Kiln waste exhaust heat was captured with a high-pressure hot water coil in a bypass duct with a fan and separate stack. This allows for our damper system to bypass air to the heat recovery, or during times where the heat is not required, we can still exhaust the heat through the existing stacks.

-

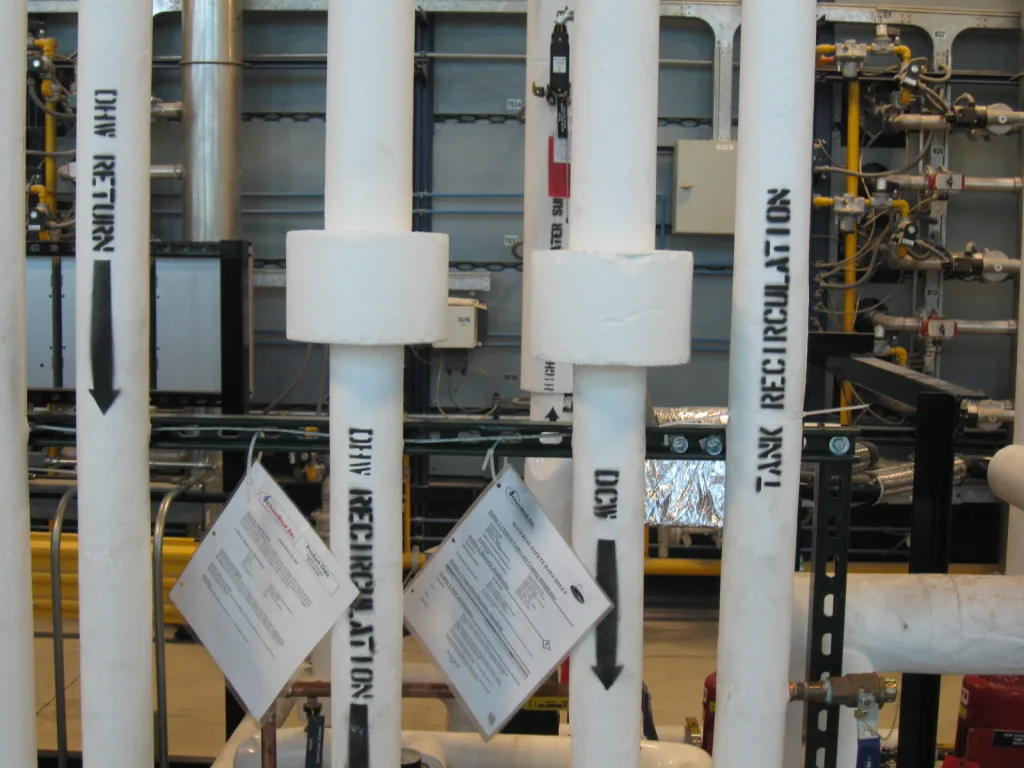

A high pressure closed loop hot water system operating from 120° to 350° F collects and transfers the thermal energy. A brazed heat exchanger heats the domestic water from 55° to 200° F. The higher domestic hot water storage temperature allows a smaller volume of storage for the domestic hot water storage temperature allows a smaller volume of storage for the domestic hot water system. Supply to the domestic hot water system is controlled to 120°F using a thermostatic mixing valve.

-

The Kohler Pottery heat recovery project can recover up to 254,000 therms per year. This project saves $178,000 per year of natural gas, with 50% of project cost provided by Wisconsin Focus on Energy, Kohler’s payback period was only 2.5 years.