Lakeside Foods

Energy Efficient Ammonia Refrigeration - Lakeside Foods

“The Rohde Brothers team does an outstanding job communicating with me all deadlines and any changes taking place throughout the project. Rohde’s foreman on the stand-alone freezer project at Lakeside Foods work hand-in-hand with our foreman to ensure the project was completed safely and on time,”

“Because of their (Rohde Brother’s) professionalism and ethical work practices…it is easy to see how they’ve been successful for so many years.”

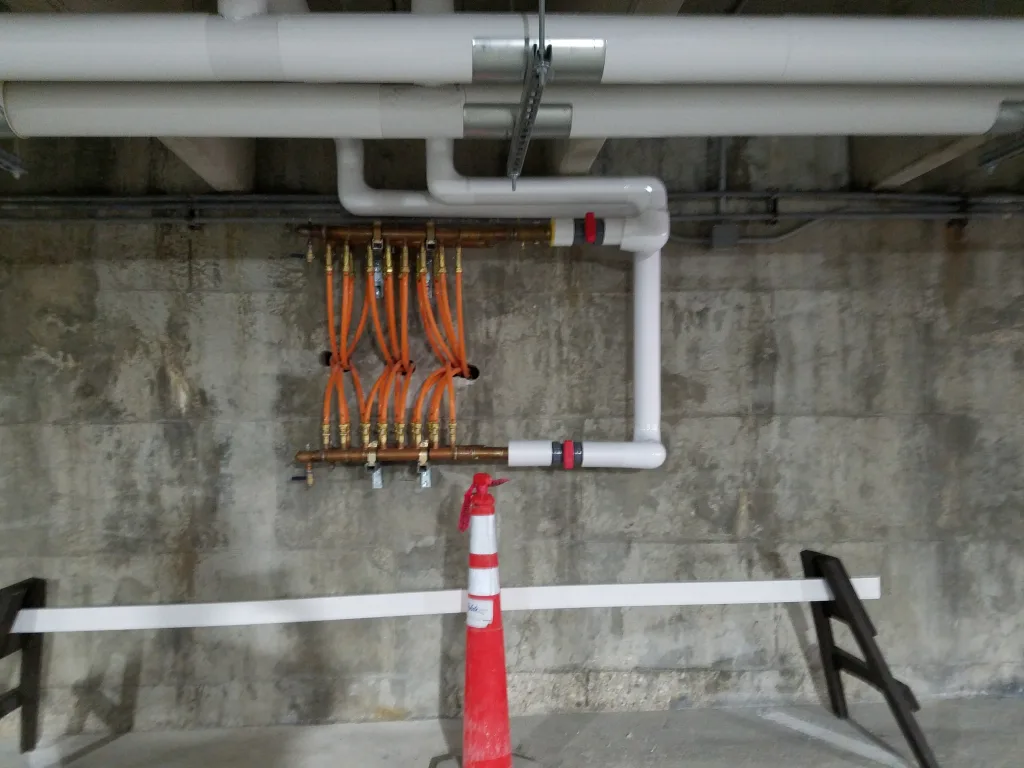

Rohde Brothers Inc. installed the refrigeration and HVAC systems for a new stand-alone freezer building for Lakeside Foods in Manitowoc. The freezer is 138,000 square feet and operates at -10°F. The aggressive construction schedule for this project did not allow room for any missteps or delays in any phase of the work. The complex mechanical systems within the building required careful coordination, Rohde used 3D building information and shop prefabrication, instead of the traditional method of field coordination to avoid substantial delays in the schedule.

Customized Solution:

- Rohde used 3D building information and shop prefabrication to the fullest extent possible in order to reduce field manpower requirements, increase the speed of project delivery, and to ensure space was allocated to fit everything required by all contractors including plumbing and electrical contractors

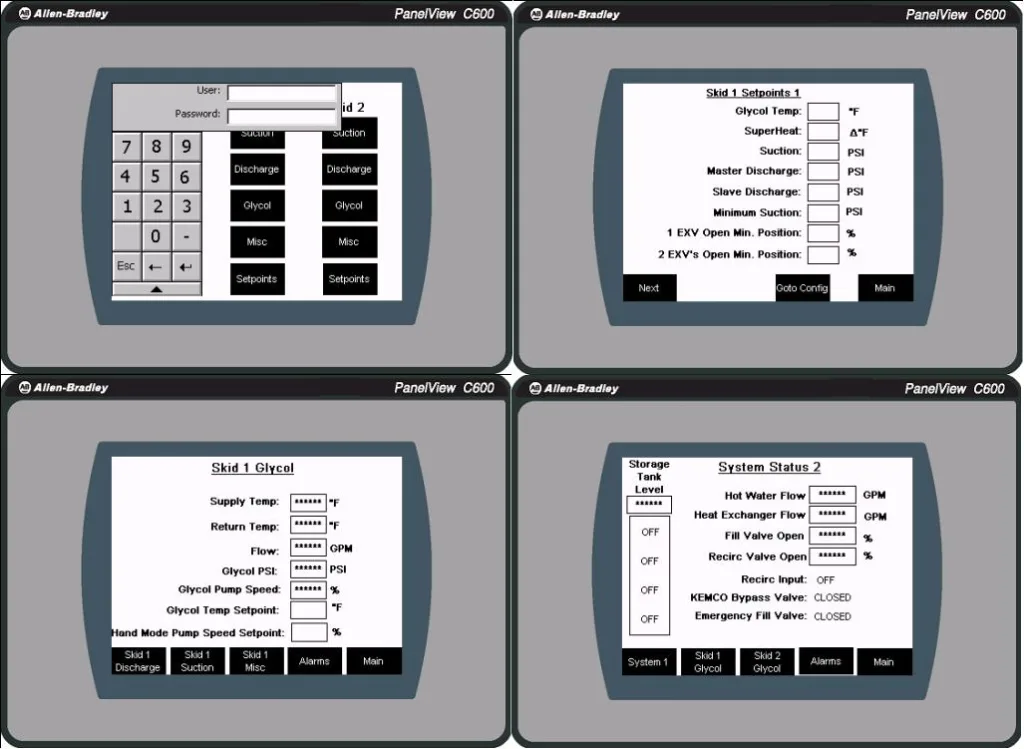

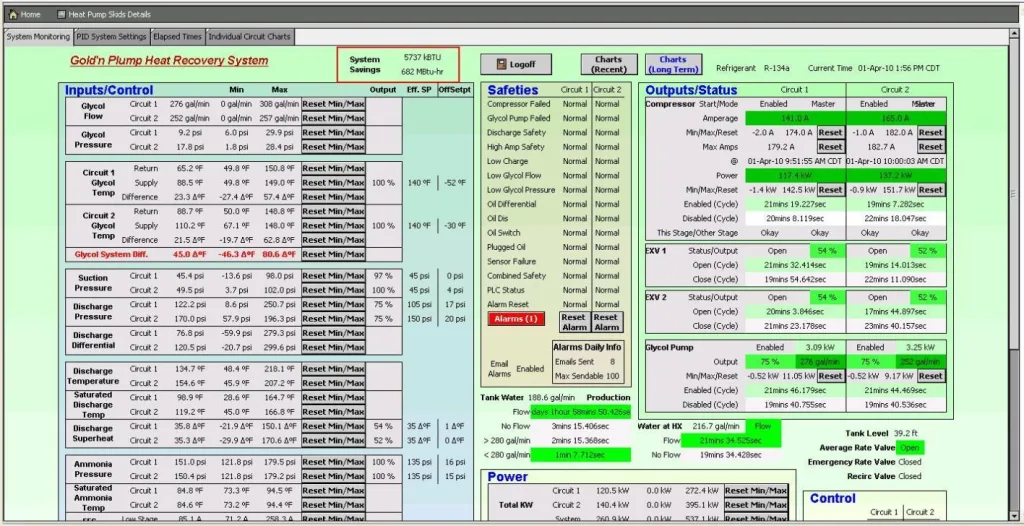

- Allen-Bradley programmable logic control system was employed at the facility to continuously monitor and control the entire system to ensure safe and energy efficient operation

- Rohde fabricated a variety of system components in our shop including ductwork, piping, and control panels

- Rohde built subassemblies as large as practical considering trucking and material handling requirements. Building components before space on site was available helped us maintain the demanding project schedule

- Rohde installed all components for the freezer including: