by Rohde Brothers | Feb 12, 2024

Waste Water Treatment Plant Upgrade - City of Portage

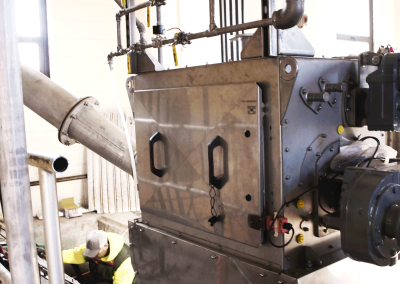

Effluent piping to next phase – Old piping

Pump – old auger style washer

Band Screen fine screener

The city of Portage, WI rests on the banks of the Wisconsin River and is one of Wisconsin’s oldest cities.

The city decided to upgrade and update parts of its waste water treatment headworks in an attempt to improve the overall condition of it’s facility and it’s processes.

The job consists of a center flow band fine screen system with an integrated compactor. The equpment was very specific and built in Austrailia. To our knowledge this company is the only firm to make this exact equipment. The equipment is self cleaning and can be operated using a number of configurations.

The job also consisted of piping and pumps which happen in a second phase. Driver motors, gear reducers, and piping all needed to be installed to fully upgrade the system.

Customized Solution:

- RETROFIT a new center flow fine screen vertical screener with an integral compactor into the facility. With all new controls and piping to the next phase of the treatment process.

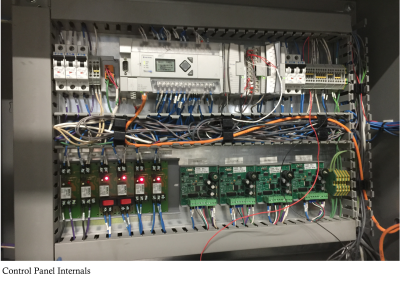

- Controls for the equipment were installed per NEC specifications to operate and consist of 480 volt primary panel with PLC and an operator interface which can operate the screen, spray wash, and compactor.

- New piping for solids coming from the screener

- New piping and pumps for effluent to move liquid into other areas of the treatment plant

by Rohde Brothers | Feb 5, 2024

Waste Water Treatment Plant Upgrade - Village of Eden

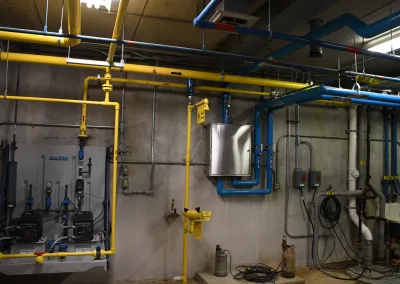

Eden Alum Tank and Plumbing

Process Automation Interface

Pump room with Alum Mixer

Hot Water and Softener for building water

Alum tank, pump, plumbing and controls

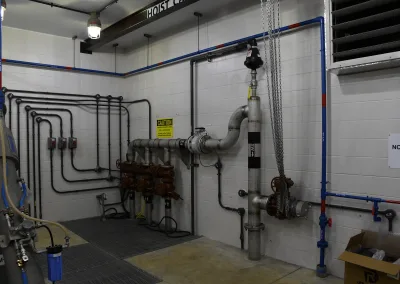

Plant Head Valves and Piping

Unit Heaters in the Screener Room

Three Kaeser CB 131 Rotary Lobe Blowers

Pump Room with connecting piping

Side Vents on Head Waters Station

Solid Waste Tank Plumbing

The Village of Eden, WI was looking to renovate and expand its waste water treatment capacity due to outdated equipment and growing needs.

The village contracted with CDSMITH and Rohde Brothers, Inc. to completely retrofit its current waste water plant. The project consisted of several changes which enhanced capacity and updated the operation from a 100% manual one, to an automated plant which can be monitored and operated remotely by one person. The upgrade increased overall capacity of some parts of the plant 300% and includes new piping, pumps, blowers, HVAC, a new Alum tank and system, a new skimmer, and completely new sensors and controls throughout.

Customized Solution:

- All new HVAC throughout the system included fans, blowers, exhaust, furnaces, and room heating units.

- A new alum injection system with new tank, mixer, and pumps.

- New and much more efficient variable speed pumps to move effluent around the various operation stages of the plant.

- New and expanded piping throughout the facility.

- A new testing center which automates the testing process.

- 3 Kaeser rotary lobe blower systems which functionally increase the airation capacity 3x while saving energy.

- Several fans and vent fans were installed to maintain breatheable air inside all areas of the facility.

by Rohde Brothers | Feb 2, 2024

Waste Water Treatment Plant Upgrade - City of Appleton

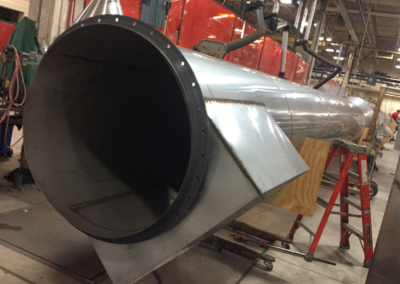

Appleton WWTP sludge press discharge conveyor – vert dimensione

Appleton WWTP sludge press discharge conveyor closest to elevator 2

Appleton WWTP sludge press discharge conveyor closest to elevator

The city of Appleton is one of the fastest growing cities in North East Wisconsin, and they needed to upgrade and grow the capacity of their wastewater treatment plant.

To compensate for all the growth a plan was made to double the size of the solid waste conveyer system and structural walkway, they looked to Rohde for help.

Rohde also added an air handler and related ducting to properly ventalate the processing area where acid washing takes place. Then hoods which help to clear the air over the acid washing operations were installed to de-mist/exfiltrate the acid fumes to make the space habitable for workers. Rohde also installed new duct and vent hoods over the conveyor system being built.

Rohde was also the plumbing and utilities contractor for this project which meant completely demolishing the old storm drains in the solid waste storage building and replacing it. Rohde also constructed an underground storm water system in the new addition.

Customized Solution:

- 3D modeling used to design and prove the underground storm drain system in the new addition.

- A new main conveyor system was provided by Schwing Bioset and installed by Rohde Brothers team members.

- A new conveyor system was added to move waste solids to the new expansion which was designed and built by Rohde Brothers, then installed by Rohde Mechanics.

- Vent hoods and associated ductwork was provided by Rohde Brothers in-house metal fabrication team.

- A total of 21 exhaust fans were installed in the main storage area as well as the new addition to properly exfil gasses from the facility.

by Rohde Brothers | Jan 25, 2024

Unique Ice Storage System - Masters Gallery Foods

“I enlisted Mike and his team at Rohde Brothers early in the conceptual planning stages of the project to discuss the plant refrigeration systems. Drawing from our collective years of experience, we collaborated to develop a plan taking a holistic approach to the HVAC and refrigeration systems design. We incorporated a unique ice storage system, geothermal and waste heat recovery to deliver comparable energy efficiency without the need for ammonia. The resulting systems are easier to maintain and offer a lower life-cycle cost than following the traditional approach,”

Engineering Manager, Masters Gallery Foods

When Masters Gallery Foods decided to build a new plant for cutting and shredding cheese in Oostburg, Wisconsin they looked to Rohde Brothers, Inc.

The new 2-story, 187,230 square foot state-of-the-art facility included maintenance friendly and energy efficient systems that utilize standard equipment in unique ways including a unique ice storage system, geothermal and waste heat recovery.

In most food processing facilities, the HVAC, process utilities and refrigeration systems are designed independently. In this case, Rohde’s team was able to take a unique, more holistic approach, reducing initial construction costs as well as the cost of ongoing energy and maintenance.

Snow melt tubing during installation

Sheet metal ductwork fabricated in our shop

Masters – Snow Melt Heat Exchangers

Masters – Cooling Tower_edited

Masters – Cooling Tower with Pumps

Masters – Chillers Being Fabricated in Shop

Installed sheet metal ductwork

Ice Storage Silo & Cooling Tower Supporting the Industrial Refrigeration System

Customized Solution:

- 3D modeling used to facilitate an aggressive construction schedule, and to coordinate the complex mechanical and electrical system installation.

- Waste heat from the chillers, hydraulic power unit and air compressors was utilized in the heat pump units to provide heating and cooling of the offices, data and server rooms as well as heat for the snow melt and in-floor hydronic heating systems.

- A geothermal pond loop system provided cooling for excess heat to minimize need for the cooling towers.

- Refrigeration systems were designed for future expansion to triple plant capacity in two additional phases of construction.

- The new facility included a refrigerated bulk storage warehouse, three processing lines, packaging, a refrigerated shipping warehouse, office and a test kitchen.

- Major equipment supplied includes four food-grade air handling units, five heat-pump roof-top units, four fan-coil heat-pumps, twelve ceiling hung evaporators, one packaged roof-top unit, two chillers, two ice-makers, cooling tower, pumps, variable area volume boxes, fan coil units, and exhaust fans.

by Rohde Brothers | Jan 22, 2024

Waste Heat Recovery - Kohler Company

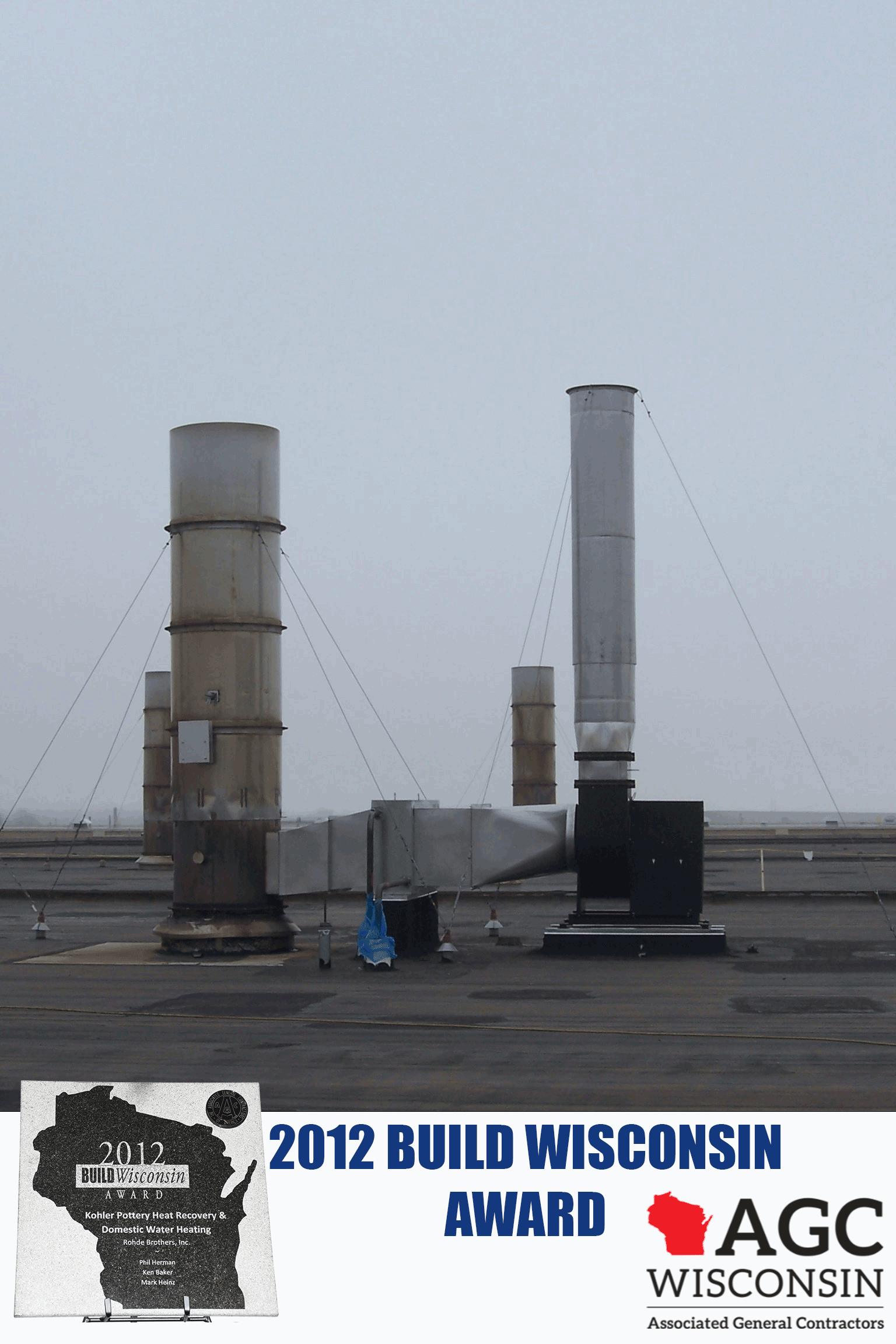

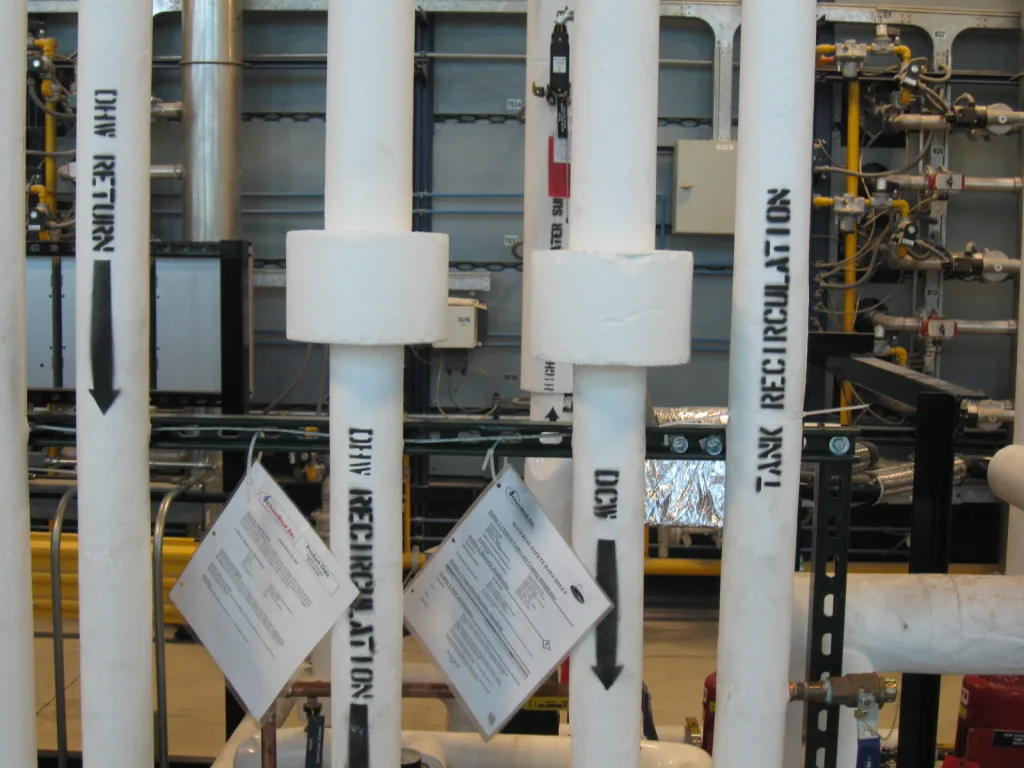

Kohler Company was looking for a way to recover the heat emitted from production in their Pottery facility. Kohler has four large kilns for pottery vitrification (turning clay to glass) with discharge stack temperatures above 800°F. Kohler Pottery conveniently has a large demand for lower temperature heat both for pottery drying and for domestic hot water generation. Kohler Pottery uses about the 18,000 gallons of 120°F hot water they utilize per day for production and for domestic purposes. In addition, Kohler uses a hot air at 250°F for their produce dryers.

The Kohler Pottery Heat Recovery project consisted of recovering high temperature heat from three shuttle kilns, and one tunnel kiln. The recovered heat was used as a heat source for five shuttle dryers and the domestic hot water system. The firing process in the shuttle kiln creates waste heat at a maximum temperature of 1,000°F at 65,000 pounds per hour. Total amount of heat recovery for a firing cycle on a shuttle kiln is 660,000 BTU’s. Additionally, Kohler’s Tunnel Kiln supplies the system with 1,540 MBH of heat constantly. Kohler’s tunnel kiln is rarely shut down as it takes 24 hours for a part to pass through the tunnel and shutdowns actually damage the kiln due to thermal expansion and contraction.

Customized Solution:

-

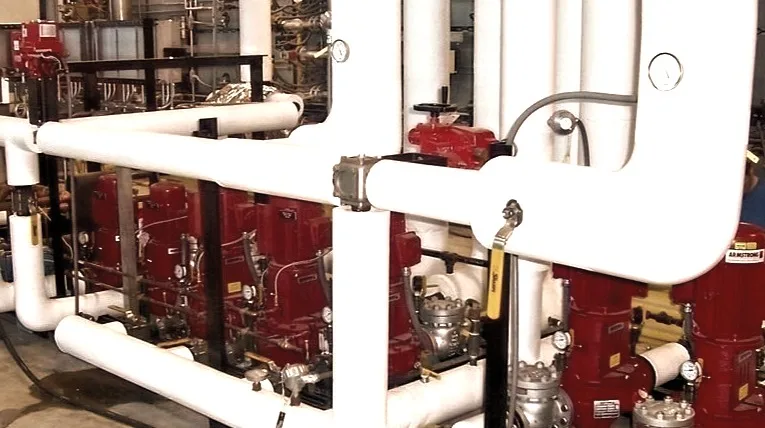

Using 3D modeling and FEA, the Rohde team designed a custom thermal storage tank capable of holding 4,000 gallons of water at 400 PSIG. Typical storage systems run to 125 PSIG. The pump skid was pre-piped and pre-wired in the Rohde shop to minimize disruption of plant operations. The pump skid included an Allen-Bradley PLC for control of the pumps and heat recovery system. A web-based Honeywell controller provides graphical user interface for operating and monitoring the PLC.

-

Enabled heat recovery of 254,000 therms per year; saving The Kohler Company $178,000 in natural gas costs within the first year. With 50% of the project cost funding provided by WI Focus on Energy, the payback period was only 2.5 years.

-

Kiln waste exhaust heat was captured with a high-pressure hot water coil in a bypass duct with a fan and separate stack. This allows for our damper system to bypass air to the heat recovery, or during times where the heat is not required, we can still exhaust the heat through the existing stacks.

-

A high pressure closed loop hot water system operating from 120° to 350° F collects and transfers the thermal energy. A brazed heat exchanger heats the domestic water from 55° to 200° F. The higher domestic hot water storage temperature allows a smaller volume of storage for the domestic hot water storage temperature allows a smaller volume of storage for the domestic hot water system. Supply to the domestic hot water system is controlled to 120°F using a thermostatic mixing valve.

-

The Kohler Pottery heat recovery project can recover up to 254,000 therms per year. This project saves $178,000 per year of natural gas, with 50% of project cost provided by Wisconsin Focus on Energy, Kohler’s payback period was only 2.5 years.