Unique Ice Storage System - Masters Gallery Foods

“I enlisted Mike and his team at Rohde Brothers early in the conceptual planning stages of the project to discuss the plant refrigeration systems. Drawing from our collective years of experience, we collaborated to develop a plan taking a holistic approach to the HVAC and refrigeration systems design. We incorporated a unique ice storage system, geothermal and waste heat recovery to deliver comparable energy efficiency without the need for ammonia. The resulting systems are easier to maintain and offer a lower life-cycle cost than following the traditional approach,”

When Masters Gallery Foods decided to build a new plant for cutting and shredding cheese in Oostburg, Wisconsin they looked to Rohde Brothers, Inc.

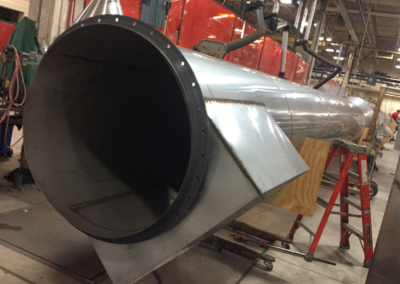

The new 2-story, 187,230 square foot state-of-the-art facility included maintenance friendly and energy efficient systems that utilize standard equipment in unique ways including a unique ice storage system, geothermal and waste heat recovery.

In most food processing facilities, the HVAC, process utilities and refrigeration systems are designed independently. In this case, Rohde’s team was able to take a unique, more holistic approach, reducing initial construction costs as well as the cost of ongoing energy and maintenance.

Customized Solution:

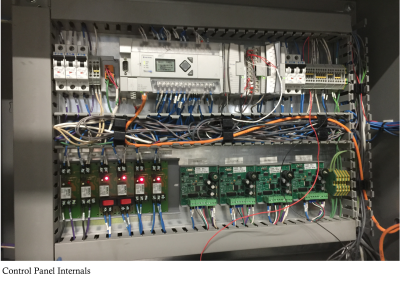

- 3D modeling used to facilitate an aggressive construction schedule, and to coordinate the complex mechanical and electrical system installation.

- Waste heat from the chillers, hydraulic power unit and air compressors was utilized in the heat pump units to provide heating and cooling of the offices, data and server rooms as well as heat for the snow melt and in-floor hydronic heating systems.

- A geothermal pond loop system provided cooling for excess heat to minimize need for the cooling towers.

- Refrigeration systems were designed for future expansion to triple plant capacity in two additional phases of construction.

- The new facility included a refrigerated bulk storage warehouse, three processing lines, packaging, a refrigerated shipping warehouse, office and a test kitchen.

- Major equipment supplied includes four food-grade air handling units, five heat-pump roof-top units, four fan-coil heat-pumps, twelve ceiling hung evaporators, one packaged roof-top unit, two chillers, two ice-makers, cooling tower, pumps, variable area volume boxes, fan coil units, and exhaust fans.