by Rohde Brothers | Jan 30, 2025 | Cold storage, Food Production, HVAC, Projects, Service

Maintaining precise environmental conditions is not just a preference. In fact, in food processing, it’s a necessity. From preserving product quality to meeting strict food safety standards, HVAC systems play a critical role in ensuring temperature control, air quality, and energy efficiency. Let’s explore how food manufacturers can optimize their HVAC systems to achieve these goals while staying compliant with food safety standards.

Why HVAC Matters in Food Manufacturing

Food manufacturing facilities face unique challenges every day. The need to control temperature, humidity, and airborne contaminants in production and cold storage is paramount for several reasons:

Preserving Product Quality: Temperature and humidity levels may impact the product flavor, mouth feel, and other attributes. Fluctuations can compromise food integrity, texture, and shelf life.

Ensuring Food Safety Compliance: standards, such as those set by the FDA and USDA, demand strict environmental controls to prevent contamination.

Worker Comfort and Productivity: Stable air quality and temperature improve working conditions for employees.

Energy Costs: HVAC systems account for a significant portion of a facility’s energy use. Efficient systems can drastically reduce costs. The use of waste heat to control office and/or production temperature in winter months can save thousands of dollars each year.

When you don’t have control over your indoor air, you will not have control over product quality or freshness.

Optimizing HVAC Systems: Key Strategies

Prioritize Temperature and Humidity Control Systems

Zoned HVAC Systems: Divide your facility into zones based on specific temperature, pressure, and humidity requirements. . Zoned systems allow you to tailor settings based on operational requirements of the facility, ensuring the best possible conditions in each space without overworking the system.

Real-Time Monitoring: Install advanced sensors to track temperature and humidity in real-time. Automated alerts can help identify and correct issues before they impact production. A digital interface can be developed that allows readings to be viewed and adjusted at-a-glance.

Enhance Air Filtration and Ventilation

High-Efficiency Filters: Use HEPA or ULPA filters to capture airborne particles and contaminants, protecting both products and workers.

Positive and Negative Air Pressure Zones: Maintain positive pressure in clean areas to prevent contaminants from entering, and negative pressure in waste or processing areas to contain odors and debris.

Air Turnover: Make up air is required to provide a continuous flow of fresh air into the facility to maintain air quality and remove contamination. ASHRAE standards recommend minimum outside air exchanges based on the occupancy of the space. It is often beneficial to increase the amount of fresh air exchange.

Boost Energy Efficiency

Upgrade Equipment: Use Variable Frequency Drives (VFD’s) to control fans and pumps to conserve energy. Consider high-efficiency HVAC units and geothermal systems, which adapt to changing heating and cooling needs conserving energy in the process.

Preventive Maintenance: Regularly clean ducts and filters, inspect refrigerant levels, and replace worn belts, motors, and actuators (dampers) to keep systems running efficiently.

Energy Recovery Ventilators (ERVs): Recover waste heat, humidity or cooling from exhaust air and push that heat to office or production areas to reduce energy consumption.

Room Cleaning Cycles: At certain times when facilities are undergoing cleaning with hot water, cycling the space with 100% outside air will more efficiently remove the excess humidity and heat and require less overall maintenance.

Meet Sanitary Standards with Specialized Design

Smooth Surfaces: Ensure HVAC components, such as ducts and vents, are made from easy-to-clean stainless-steel materials and properly sloped to avoid ponding and contamination buildup.

Condensation Control: Prevent moisture buildup on HVAC surfaces with proper insulation and drainage to block mold and bacteria growth.

Regulatory Compliance: Partner with Rohde Brothers, Inc. HVAC specialists who understand food manufacturing standards, such as FSMA, and design systems to meet these strict guidelines.

Incorporate Smart Controls

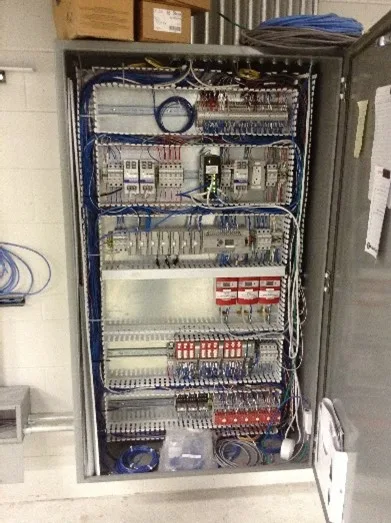

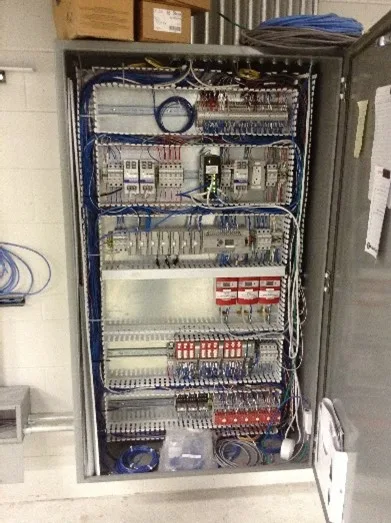

Integrated Building Management Systems (BMS): Centralize HVAC controls to adjust settings based on production schedules and occupancy levels, reducing unnecessary energy use.

Predictive Analytics: Use data driven tools to forecast HVAC demand based on historical data, weather patterns, and production schedules.

Benefits of Optimized HVAC Systems

HVAC can make up 40-60% of overall energy consumption in a food manufacturing facility. By optimizing HVAC systems, food manufacturers can realize several advantages:

Cost Savings: Energy-efficient systems lower utility bills because they use up to 30% less energy and reduce maintenance expenses.

Regulatory Compliance: A well-maintained HVAC system ensures adherence to food safety and sanitary standards. Experts like Rohde Brothers guide facilities leaders on changes to these standards and how to most effectively comply with them.

Improved Product Quality: Precise temperature and air quality control help maintain the integrity of food products. This positively impacts the business in many ways including sales, marketing, quality, traceability and so on.

Sustainability Goals: Reduced energy consumption contributes to environmental sustainability efforts. These efforts save money and time in the long run.

Ready to Build a Better HVAC System?

Optimizing HVAC systems for food manufacturing facilities requires careful planning and expertise. Whether you’re upgrading an existing system or designing a new one, Rohde Brothers, Inc. is here to help. Our experienced engineers and craftsmen specialize in creating energy-efficient, regulation-compliant HVAC solutions tailored to the unique needs of food manufacturers.

Let’s build something together.

by Rohde Brothers | Dec 6, 2024 | Food Production, HVAC, Service, Uncategorized

Boost Efficiency, Prevent Downtime, and Save Money

As winter approaches, facility managers and maintenance teams face unique challenges in keeping industrial mechanical systems running smoothly and efficiently. Cold temperatures can lead to increased wear, higher energy consumption, and unexpected downtime. But with a proactive winter maintenance plan, you can protect your mechanical assets, optimize performance, and reduce operating costs. In this guide, we cover the most critical maintenance tasks for winter, helping your facility remain productive, efficient, and resilient all season long.

Service and Calibrate HVAC Systems for Optimal Efficiency

Key Points: Heating systems, filters, controls, and ventilation.

- Inspect Heating Systems: Boilers, furnaces, and other heating equipment should be professionally inspected, cleaned, and calibrated for winter use. Well maintained and tuned burners operate at peak efficiency and minimizes energy waste.

- Replace Air Filters: Dirty or clogged filters restrict airflow, forcing HVAC systems to work harder. Replacing filters reduces strain on equipment, saves energy, and keeps indoor air quality high.

- Check Ventilation: Proper ventilation is crucial in winter. Too little airflow causes poor air quality. Too much outside airflow wastes energy. Inspect and clear any blockages in ventilation ducts to ensure a continuous flow of fresh air and reduce strain on HVAC systems. Confirm dampers are working properly.

Savings Insight: Efficient HVAC systems can reduce energy bills more than 20% during winter, a significant savings in an industrial setting.

Prepare and Protect Pipes to Prevent Freezing

Key Points: Insulation, heat tracing, and water temperature.

- Insulate Exposed Pipes: Insulation helps maintain pipe temperatures, reducing the risk of freezing and subsequent damage as well as minimizing energy loss.

- Use Heat Tracing for Critical Pipes: Heat tracing cables provide direct heat to pipes, which is especially beneficial for critical process piping. Ensure the system is operational and calibrated to activate during low temperatures. Focus on pipes in unheated areas or those located near exterior walls.

- Monitor Water Temperatures: Cold weather can affect water temperatures, impacting certain processes. Consistently monitor and adjust to maintain safe temperatures that won’t stress pipes or equipment.

Savings Insight: Proactive pipe maintenance helps prevent costly repairs, downtime, and potential damage to the facility due to burst pipes.

Perform Routine Maintenance on Pumps and Motors

Key Points: Lubrication, seals, and vibration analysis.

- Lubricate Moving Parts: Cold weather can cause lubricants to thicken, leading to additional wear on pumps and motors. Regularly lubricate moving parts to reduce friction and ensure smooth operation. Be careful not to over-lubricate, which can cause increased friction and reduced efficiency.

- Inspect and Replace Seals: Cold weather can harden seals, leading to leaks or pressure drops. Inspect seals on all pumps and motors and replace any showing signs of wear.

- Conduct Vibration Analysis: Excessive vibration can be a sign of imbalance or misalignment in pumps and motors. Regular vibration analysis helps identify potential issues early, reducing the risk of breakdowns.

Savings Insight: Properly maintained pumps and motors consume less energy and have a longer lifespan, reducing the need for costly replacements.

Maintain Water and Wastewater Treatment Systems

Key Points: Tank heaters, drain lines, and pump inspections.

- Install or Test Tank Heaters: Cold temperatures can cause water in outdoor tanks to freeze, disrupting processes. Ensure tank heaters are installed and functioning properly to maintain consistent temperatures.

- Inspect and Clear Drain Lines: Blocked drains can freeze over in winter, leading to backups or overflows. Regularly clear drain lines to prevent ice buildup and ensure smooth water flow.

- Pump Inspections: Winter can be tough on pump systems due to cold, thickened fluids. Inspect pumps for signs of wear and verify that they can handle increased resistance from colder, thicker fluids.

Savings Insight: Preventing freeze-related issues in water systems helps avoid unexpected downtime and maintains process integrity.

Inspect and Test Backup Power Systems

Key Points: Generators, fuel levels, and load testing.

- Generator Inspections: Power outages are more common in winter, so it’s essential to ensure that backup generators are ready to handle unexpected demand. Conduct a full inspection, checking fuel levels, battery health, and connections.

- Perform Load Testing: Load testing helps verify that your backup system can handle the facility’s power needs during an outage. Schedule these tests regularly to avoid unpleasant surprises.

- Check Fuel Quality and Storage: Cold weather can cause diesel fuel to gel. Make sure fuel tanks are properly maintained and consider using winter-grade fuel or additives to prevent gelling.

Savings Insight: Reliable backup power prevents costly downtime, safeguarding your operations even during winter storms.

Implement Energy Management and Monitoring Systems

Key Points: Smart controls, energy monitoring, and data analysis.

- Smart Control Systems: Consider installing or updating control systems to automate temperature adjustments and regulate energy use based on facility needs.

- Continuous Energy Monitoring: Monitoring energy usage across heating, ventilation, and process systems gives facility managers insight into where energy use spikes, allowing for targeted efficiency improvements.

- Data Analysis for Efficiency Gains: Reviewing data from energy management systems can reveal areas for improvement, such as adjusting heating levels or scheduling system downtimes.

Savings Insight: Energy management systems provide actionable insights, allowing you to reduce unnecessary energy expenses and optimize equipment performance.

Final Thoughts: Plan Proactively to Save Big This Winter

Winterizing industrial mechanical systems isn’t just about getting through the season—it’s about running a safer, more efficient, and cost-effective operation all winter long. By implementing these maintenance steps, facility managers can reduce the risk of unexpected downtime, protect valuable equipment, and significantly reduce energy costs.

Ready to keep your facility winter-ready and efficient? Let’s build something together.

Winter is coming, and your industrial mechanical systems need to be ready. Don’t let freezing temperatures cause costly downtime, skyrocketing energy bills, or unexpected repairs.

Download our Essential Winter Maintenance for Industrial Mechanicals Checklist to:

✔ Boost HVAC efficiency and cut energy costs by up to 20%

✔ Prevent pipe freezes and protect critical infrastructure

✔ Extend the lifespan of pumps, motors, and other essential systems

✔ Ensure backup power is ready for winter storms

Equip your team with a proven step-by-step guide to keep your facility running smoothly, efficiently, and safely all winter long. Just fill the form out and we’ll send the checklist directly to your inbox.

by Rohde Brothers | Mar 19, 2024 | HVAC, Service

As we step into 2024, the HVAC industry continues to evolve with technological advancements and a growing focus on efficiency and sustainability. Updates to state and municipal codes require increasingly efficient systems to protect the environment and the health of occupants. For engineers and facility managers, staying ahead means adapting to these changes and implementing state-of-the-art strategies to optimize HVAC system performance. This article dives into the latest techniques and technologies that are shaping the future of HVAC systems in commercial and industrial settings.

Advanced Control Systems:

The heart of modern HVAC efficiency lies in advanced control systems. These systems employ real-time data analytics and machine learning algorithms to continuously monitor and adjust settings for optimal performance. For example, smart thermostats and Building Automation Systems (BAS) can now predict occupancy patterns, adjust temperatures based on real-time weather data, and identify areas to optimize. Occupancy sensors and carbon dioxide sensors enable the BAS to optimize for comfort and efficiency.

Variable Frequency Drives (VFDs):

VFDs have become the standard in energy conservation. By controlling thespeed of motor-driven equipment based on demand, VFDs significantly reduce energy consumption. In 2024, the integration of VFDs with BAS for real-time adjustments based on occupancy and usage patterns is a game changer, offering potential energy savings of up to 30-40% in systems like air handlers, chillers, and water pumps.

High-Efficiency HVAC Equipment:

The shift towards high-efficiency HVAC equipment is more pronounced than ever. The international mechanical code and international energy code require energy efficiency improvements. The latest models of chillers, condensers, and heat pumps come with higher Seasonal Energy Efficiency Ratios (SEER), Energy Efficiency Ratios (EER), and Coefficient of Performance (COP) values. For instance, modern chillers incorporate magnetic bearing technology, permanent magnet motors, and variable speed compressors, reducing energy consumption and maintenance needs.

Indoor Air Quality (IAQ) Management:

IAQ has taken center stage, especially in the wake of global health concerns. Advanced HVAC systems now integrate IAQ sensors that monitor and control air quality parameters like CO2 levels, humidity, and airborne pollutants. Regular maintenance of air filters, ducts, and employing, ionization and UV-C light technology for air purification are key strategies in maintaining optimal IAQ.

Geothermal Heat Pump Systems:

The use of geothermal heat pump systems is on the rise, leveraging the stable temperatures of the earth to provide heating and cooling. These systems offer significant energy savings and lower greenhouse gas emissions compared to traditional HVAC systems. The high upfront costs are typically more than offset by rebates, tax credits available through state and federal programs, and other incentives. This makes using these energy efficient systems much more attractive. Other green refrigerants are also considered regularly due to their unique advantages and cost savings.

Retrofitting and Upgrading:

For many facilities, completely overhauling the HVAC system is not feasible. Thus, retrofitting becomes a vital strategy. In 2024, consider retrofitting options such as adding Variable Frequency Drives (VFDs) and upgrading to smart thermostats or full building automation systems when it is time for replacements or upgrades. Replacing outdated components with high-efficiency alternatives provide a cost-effective way to enhance efficiency and air quality.

Conclusion:

The year 2024 presents exciting opportunities for optimizing HVAC systems in commercial and industrial environments. By embracing advanced control systems, VFDs, high-efficiency equipment, robust IAQ management, innovative geothermal solutions, and strategic retrofitting, engineers and maintenance directors can significantly improve system performance, reduce energy costs, and contribute to a more sustainable future. At Rohde Brothers, Inc., we are committed to providing innovative solutions and expertise to help you achieve these goals.

Choose Rohde Brothers, Inc. for HVAC Excellence

With Rohde Brothers, Inc., you’re choosing a partner committed to innovative, efficient, and sustainable HVAC solutions.

Contact us today to discuss how we can elevate your HVAC systems, reduce your energy footprint, and ensure optimal performance for years to come.

by Rohde Brothers | Jan 23, 2024 | Service

Choosing a commercial mechanical service partner is more than just another business decision; it is critical to the life of your building and your business. Why is it so critical? Mechanical systems are what make your facility functional and comfortable. For industries like food production, the importance of maintaining a temperature-controlled environment cannot be overstated. Mechanical systems in the food industry can be used in the production and packaging processes as well. Having a contractor doing your service regularly will provide a level of protection for your operations that will save you time and money overall.

Excellent Service is Critical to Your Operations

Do not underestimate the repercussions of making the wrong choice but focus on the positive and you will be just fine. Besides the obvious risk of being overcharged, there is also the potential for unreliable service and frequent equipment issues. On the other side, making an informed choice can provide you with a reliable partner who not only saves you time but also significantly reduces costs over the life of your equipment by implementing quality from day one. This is particularly crucial when you consider the operational setbacks like plant or process shutdowns, which can throw your production schedules into chaos.

Step 1: Comprehensive Research

Broaden Your Search

Start with a varied and wide-reaching approach. Do not rely solely on internet search results; while they are a good starting point, remember that SEO rankings do not necessarily correlate with service quality. If you are not new to the contracting business, you are probably already working on a list of firms that have done well by you and are trusted and reliable. If you are looking to add firms to your list, try some of these:

Industry-Specific Platforms: Websites designed for your industry can be goldmines of information, offering directories, reviews, and even case studies.

Business Directories: Platforms like Yellow pages and LinkedIn can offer a snapshot of potential contractors but be mindful that they often lack detailed evaluations.

Social Media and Online Forums: These platforms can provide real-life reviews and advice. Subreddits or Quora threads related to your industry can offer insider perspectives.

Trade Shows and Local Resources: Do not underestimate the power of face-to-face interactions. Your local Chamber of Commerce can be a fantastic resource, as can industry-specific trade shows.

Word-of-Mouth and Recommendations

Talk to your business network. Colleagues or industry contacts who have had firsthand experiences with contractors can offer invaluable insights.

Online Reviews for Additional Perspective

While they should be taken with a grain of salt, websites like Yelp and Google Reviews can give you a feel for customer satisfaction and company responsiveness.

Step 2: Verify Credentials Rigorously

Insist on Certifications

Reputable companies should willingly display their industry certifications, which validate their expertise and credibility.

The Weight of Experience

An established track record is often a good predictor of future performance. Companies that have been around have typically done so by delivering consistent, high-quality service.

Step 3: Obtain and Analyze Quotes

Detailed Proposals

Request a thorough breakdown that lists

not only the cost but also the scope of

work, materials needed, labor costs, and any other factors like travel or lodging for workers.

Examine Price Factors Carefully

Ensure you understand what is driving the costs in the quotes you receive. Do not just look for the cheapest option; seek value by understanding what each line item represents.

Step 4: Evaluate Customer Service and Flexibility

Initial Interactions Matter

How a company engages with you at the beginning often sets the tone for your entire relationship. Do they respond in a timely, professional manner? Are they transparent about their capabilities and limitations? Being comfortable with your interactions is a key part of building a great relationship.

Be Mindful of Availability

Emergencies do not wait. Ensure your prospective service partner has the bandwidth and resources to assist you when unplanned issues arise. The best service partners are available when issues arise period, if your service partner makes you wait for emergency service, you can do better.

Step 5: Read the Fine Print

Understand Your Contract

Contracts safeguard both parties. A reputable company will encourage you to read the contract carefully and will gladly clarify any ambiguities.

Wrapping It Up

Navigating the complexities of selecting a commercial mechanical service provider does not have to be a minefield. With a little due diligence, you can find a partner who brings more than just technical skills and talented technicians to the table; they bring peace of mind.

About Rohde Brothers, Inc.

With more than 110 years in the business, our commitment to quality and customer satisfaction is unparalleled. Our technicians are not just skilled; they are experts in the field. They have built some of the most complex mechanical systems in the world, right here in Wisconsin. Our techs are embedded in some of the largest manufacturing facilities, and we also serve some of the smallest. Our in-house fabrication, engineering, and construction teams are ready to go to work for you.

Final Thoughts

Remember, choosing the right mechanical service provider is more than just a business decision; it is an investment in the smooth operation and success of your facility.

Contact Rohde Brothers, Inc. to take the first step toward a partnership that prioritizes your peace of mind and operational excellence. Mike Kruschke is the Service Manager at Rohde Brothers, Inc. and has decades of experience in servicing mechanical infrastructure and equipment. Click the Email Button Below to let us know how we can help.

Call for Service: 920-893-5905

by Rohde Brothers | Dec 15, 2023 | Service

As plant managers, maintenance experts, and engineering professionals, we know the backbone of any operation involving temperature-sensitive goods is its refrigeration system. It’s not just about getting and keeping products cold; it’s about efficiency, and reliability. Regular maintenance can account for 12 to 18% return annually in the form of energy savings. Not only that, according to Doug Biedenweg, an industrial process engineer, for every $1 dollar in maintenance deferred you will pay $4 in capital renewal costs when that equipment fails. That seems to make sense right? If so, don’t defer the critical maintenance that will make those savings reality.

Optimizing Operational Efficiency

In any industrial setting, operational efficiency is the cornerstone of performance and profitability.

A well-maintained refrigeration system is synonymous with optimized operational efficiency. For example, keeping coils clean and belts properly tensioned can ensure that heat transfer is always optimized. When heat transfer isn’t optimized, equipment runs longer, resulting in the use of more energy for the same amount of work. And we all know what that means: higher operational costs to the tune of 12 to 18%, and a reduced bottom line. Preventative maintenance ensures that every component is optimized, thus minimizing energy draw and the resulting operating costs.

Friction is the enemy of energy efficiency, most people agree on that, but so many times we see equipment that isn’t lubricated properly, and the compressors or fans have failed in a way that could have been avoided.

Maximizing Equipment Lifespan

From an asset management perspective, the longevity of your refrigeration system is paramount. Regular maintenance is not just about preventing breakdowns; it’s about extending the life expectancy of your equipment. When you inspect your equipment regularly you can monitor and remove debris which may be hiding an issue. Each maintenance session is an opportunity to catch early signs of wear and to replace parts before they fail. This is essential for planning capital expenditures and avoiding the financial burden of a plant shutdown. According to statistics, using critical equipment to failure costs as much as 10 times more than the maintenance program that would have prevented it. The larger the operation, the more expensive downtime becomes, in some cases costing hundreds of thousands to perhaps a million dollars per hour.

Guaranteeing Product Integrity

Product quality is non-negotiable, and a lapse in refrigeration can be catastrophic. Downtime in a cheese storage facility, for example, can be catastrophic. You spend money on the latest control systems that keep your temperatures optimal 24/7, however, downtime due to lack of maintenance can render those controls useless. Product recalls will result in lost revenue and could easily damage your reputation. Maintaining a constant temperature can be critical to your product’s flavor development, ageing, and freshness.

Minimizing Downtime Risks

Downtime is a threat to productivity and profitability. An unexpected failure can halt production lines, lead to inventory losses, and spoilage which can affect delivery schedules. Regular maintenance helps to prevent these scenarios by ensuring that potential issues are addressed before they lead to system failure.

If you’re inspecting your equipment and fixing repairs, you may be able to go for very long periods of time with no downtime. Time is money.

Prioritizing Workplace Safety

In the world of industrial refrigeration, a system failure isn’t just an operational issue—it’s a safety concern. While ammonia is typically safer than halocarbon-based refrigerants, leaks of refrigerants, such as ammonia, or halocarbons, can be hazardous. For example, ASHRAE has a classification system, and that’s an article that we don’t have the time for in this article. ASHRAE provides that a letter and number are issued to refrigerants based on their toxicity and flammability. Understanding that halocarbons are typically more flammable and with propane, ethylene, and butane in their names you quickly make the connection. The big thing to remember is maintenance is critical for the safety of the plant personnel regardless of the type of refrigerant. It’s our duty to maintain a safe working environment, and regular system inspections are a cornerstone of this commitment.

Facilitating Financial Forecasting

Effective maintenance regimes allow for predictable financial forecasting. By having a maintenance schedule, you can plan for the associated costs in your operational budget. This forward planning reduces the risk of financial surprises associated with emergency repairs and system downtime.

Predictive or preventative? Once you understand the optimal maintenance patterns for your equipment you can look at predictive maintenance as an added layer of financial forecasting and potential savings. Predictive maintenance on industrial refrigeration systems can save as much as 40% in terms of costs over reactive, and 8-12% over preventative maintenance. Why? Because adding maintenance when your equipment needs it most is optimization in the most fundamental sense.

In conclusion, the message is clear: ignoring industrial refrigeration maintenance is a risk you cannot afford. It is your responsibility to ensure that your refrigeration systems are not just functioning but are performing efficiently, safely, and in compliance with all regulations. So, it pays to prioritize maintenance, not just as a routine task, but as a strategic imperative for the success of your operations.

Keep the gears turning, the products chilled, and the operations flowing.

Rohde Brothers, Inc. has experience in designing, installing, controlling, and maintaining industrial refrigeration systems. To schedule a maintenance inspection, reach out to Service Manager, Mike Kruschke at 920-893-5905 today!

by Rohde Brothers | Jan 30, 2018 | HVAC, Service

The air quality in work environments like factories, offices, and warehouses directly impacts health, productivity, and equipment longevity. Rohde Brothers, Inc. specializes in crafting air filtration systems tailored to the unique needs of different workspaces, ensuring cleaner air for a more efficient and healthy work environment.

Why Clean Air Matters: Good air quality is essential. It’s about more than comfort—it’s about health, efficient workflow, and protecting your equipment. Our job is to provide you with a solution that addresses all these needs.

Customized Air Filtration Strategies:

High-Efficiency Filters: We incorporate HEPA filters to trap 99.97% of minuscule particles, down to 0.3 microns. In industrial settings, we often recommend MERV-13 or higher filters for capturing even finer particles, ensuring a cleaner workspace.

Tailored Make-Up Air Units (MAUs): Our MAUs are designed to replace exhausted air with fresh, filtered air. This approach not only purifies the air but also helps maintain a balanced air pressure, reducing the ingress of unfiltered air.

Tailoring to Your Space: Each workspace has its own set of challenges, from dust and debris in factories to chemical fumes in warehouses. We design systems that address these specific challenges, considering air volume, space dimensions, and the types of pollutants present.

Direct Benefits of Our Air Filtration Systems:

- Healthier Work Environment: Minimizing pollutants and allergens leads to a healthier team.

- Boosted Productivity: With cleaner air, expect fewer sick days and a more vibrant, focused team.

- Energy Efficiency: Our systems are built to be energy-conscious, reducing both environmental impact and energy costs.

- Cost Savings in the Long Run: Protecting your machinery and HVAC systems from dust and debris means less wear and tear and lower maintenance costs.

Conclusion: Rohde Brothers is committed to transforming workspaces with air quality that supports health, productivity, and machinery longevity. Our tailored air filtration solutions are designed to meet the specific needs of your industry and space. Get in touch with us to discuss how we can enhance the air quality in your workspace.