Unique Ice Storage System, Geothermal & Waste Heat Recovery

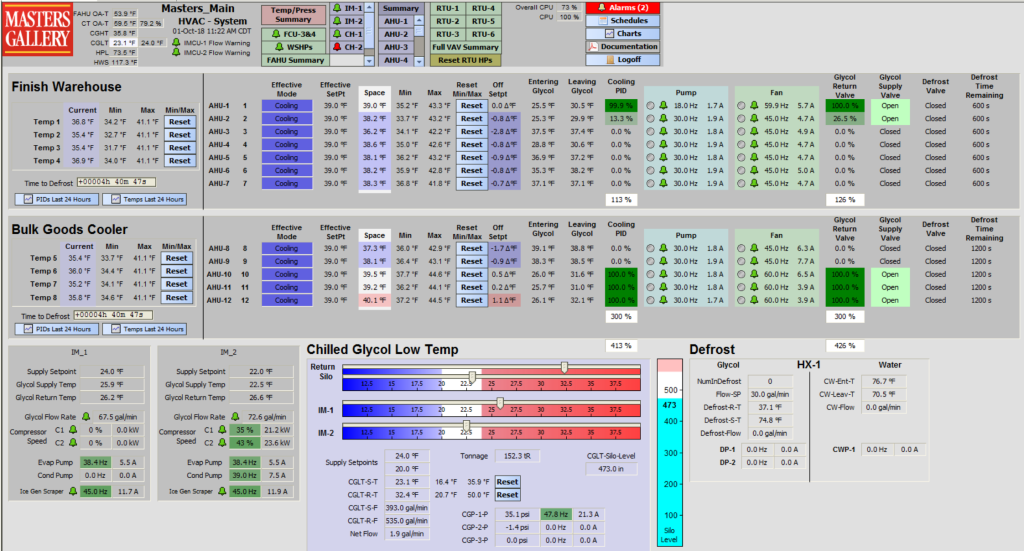

Early Collaboration for Innovation: Right from the conceptual stages, Masters Gallery Foods and Rohde Brothers collaborated closely. Mark Wirtz, Engineering Manager at Masters Gallery Foods, highlighted the benefits of this partnership. Together, we developed a holistic approach to the plant’s HVAC and refrigeration systems, integrating an innovative ice storage system, geothermal, and waste heat recovery. This approach not only enhanced energy efficiency but also reduced the need for ammonia, making the systems easier to maintain with lower life-cycle costs.

Early Collaboration for Innovation: Right from the conceptual stages, Masters Gallery Foods and Rohde Brothers collaborated closely. Mark Wirtz, Engineering Manager at Masters Gallery Foods, highlighted the benefits of this partnership. Together, we developed a holistic approach to the plant’s HVAC and refrigeration systems, integrating an innovative ice storage system, geothermal, and waste heat recovery. This approach not only enhanced energy efficiency but also reduced the need for ammonia, making the systems easier to maintain with lower life-cycle costs.

State-of-the-Art Facility Design: The new 2-story, 187,230 square foot facility features maintenance-friendly and energy-efficient systems. Utilizing standard equipment in unique ways, the plant stands as a model of modern food processing design.

Holistic Approach to Systems Design: Unlike traditional food processing facilities where systems are designed separately, our team took a more integrated approach. This not only reduced initial construction costs but also ongoing energy and maintenance expenses.

Customized Solutions:

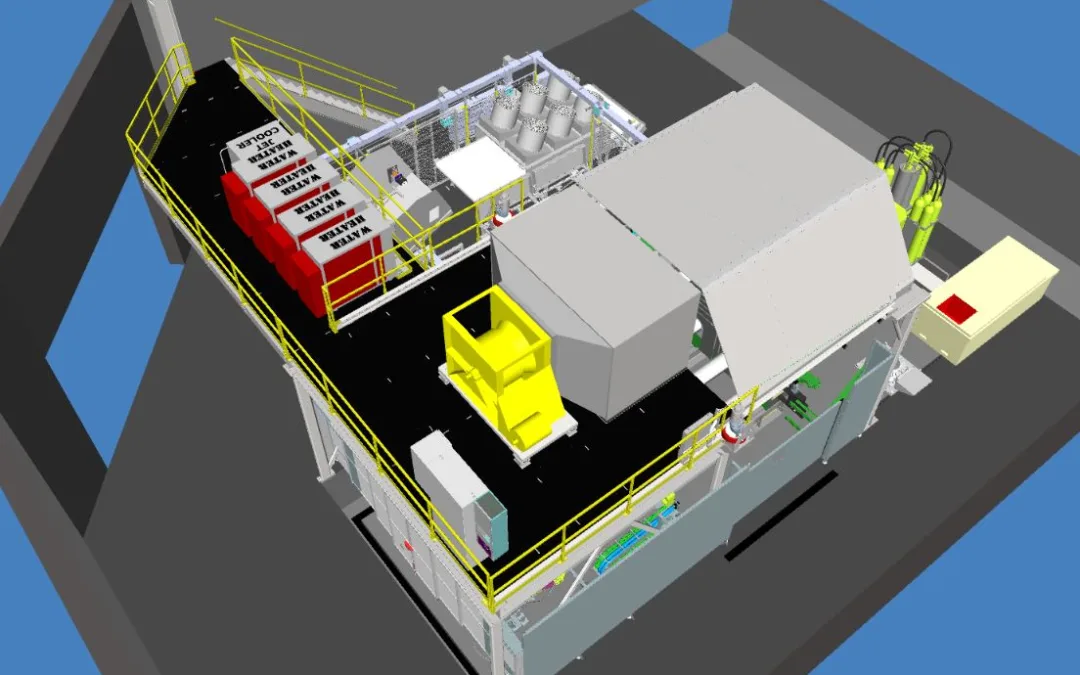

- 3D Modeling: Facilitated an aggressive construction schedule and coordinated complex mechanical and electrical system installations.

- Waste Heat Utilization: Heat from chillers, hydraulic power units, and air compressors was repurposed for heating and cooling various areas, including office spaces, data and server rooms, and for snow melt and in-floor hydronic heating systems.

- Geothermal Pond Loop System: Provided efficient cooling and minimized the need for cooling towers.

- Future-Ready Refrigeration Systems: Designed for easy expansion to triple the plant’s capacity in future construction phases.

- Comprehensive Facility Features: Included a refrigerated bulk storage warehouse, three processing lines, packaging area, refrigerated shipping warehouse, offices, and a test kitchen.

Major Equipment Installed: The facility was equipped with a wide range of high-end machinery, including food-grade air handling units, heat-pump rooftop units, fan-coil heat pumps, evaporators, a packaged rooftop unit, chillers, ice-makers, cooling tower, and various pumps and fans.

Conclusion: Masters Gallery’s new facility is a testament to Rohde Brothers’ ability to innovate in industrial HVAC and refrigeration. Our integrated, sustainable approach has set a new standard in the industry. If you’re looking for a partner to revolutionize your facility’s systems, Rohde Brothers is at the forefront of efficient and sustainable solutions.

At Rohde Brothers, Inc., we’re proud to have completed a pivotal project for Mercury Marine that won both the ABC Project of Distinction and the AGC Build Wisconsin Award in 2017. This project involved comprehensive design/build HVAC and process mechanical services for a die cast addition, along with a complete rebuild of the process piping infrastructure.

At Rohde Brothers, Inc., we’re proud to have completed a pivotal project for Mercury Marine that won both the ABC Project of Distinction and the AGC Build Wisconsin Award in 2017. This project involved comprehensive design/build HVAC and process mechanical services for a die cast addition, along with a complete rebuild of the process piping infrastructure.

The Challenge: Faced with the need to provide a safe, snow-free environment for guests, the boutique hotel sought a solution that could handle a large and varied outdoor area. This challenge called for a design that was both innovative and aggressive.

The Challenge: Faced with the need to provide a safe, snow-free environment for guests, the boutique hotel sought a solution that could handle a large and varied outdoor area. This challenge called for a design that was both innovative and aggressive.

Project Background: Kohler Pottery’s production involves four large kilns that reach temperatures above 800°F. With a substantial need for lower-temperature heat for pottery drying and domestic hot water generation, Kohler saw an opportunity to harness this waste heat. Our challenge was to capture and repurpose the heat from both shuttle and tunnel kilns effectively.

Project Background: Kohler Pottery’s production involves four large kilns that reach temperatures above 800°F. With a substantial need for lower-temperature heat for pottery drying and domestic hot water generation, Kohler saw an opportunity to harness this waste heat. Our challenge was to capture and repurpose the heat from both shuttle and tunnel kilns effectively.