Rohde Brothers, Inc. Celebrates Successful Youth Apprentice Hiring Day

Youth Apprentices at Rohde Brothers, Inc. are high school juniors and seniors who gain hands-on experience while earning school credit and a paycheck. They are required to work a minimum of 450 hours between June and May, balancing their educational and professional responsibilities effectively.

At Rohde Brothers, Inc., we believe in investing in the future of our workforce,” said Mike Rohde, President of Rohde Brothers, Inc. “Our partnerships with local educational organizations like CESA 6 and CESA 7 enable us to provide young people with the tools and opportunities they need to succeed in the trades. We are proud to be a starting point for so many skilled tradesmen.

We are pleased to introduce our current Youth Apprentices:

- Gunnar Larson, Howards Grove High School: Welding in the Shop

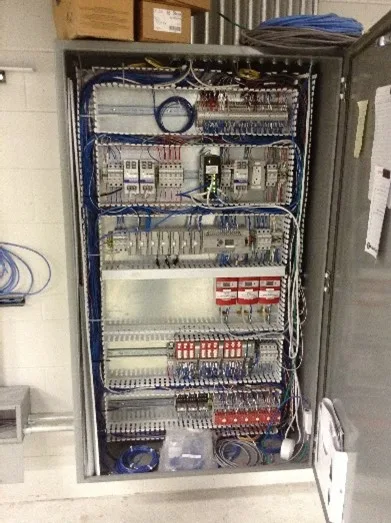

- Grayson Schamberger, Plymouth High School: Controls

- Max Trepanier, Plymouth High School: Welding GWSM

- Gage Bimmel, Oostburg High School: Construction and Welding in the Shop

- Zander Lulloff, Elkhart Lake High School: HVAC, Plumbing, and Welding

“Kaise(CESA 6) and Dana(CESA 7) have done an exceptional job mentoring these young talents,” added Claudia Krepsky, HR Manager at Rohde Brothers, Inc. “Their dedication to guiding and supporting our apprentices is a testament to our company’s commitment to nurturing future tradesmen.”

Rohde Brothers, Inc. is extremely valued among local educators as a premier place for aspiring tradesmen to begin their careers. Our dedication to hiring and training employees fosters a culture of growth and development, leading to an impressive 95% promotion-from-within rate. This approach not only benefits our employees but also strengthens our company by retaining experienced and knowledgeable professionals.

“We’re excited to welcome our new Youth Apprentices and watch them grow within our company,” added Claudia Krepsky. “Our commitment to promoting from within creates a supportive environment where employees can advance their careers and contribute to the success of our projects.”

Rohde Brothers, Inc. specializes in Process Piping, HVAC, Metal Fabrication, Industrial Controls, and Geothermal Systems for energy savings. Our extensive engineering expertise and comprehensive project capabilities ensure that we deliver cost-effective and efficient solutions to our commercial and industrial clients.

About Rohde Brothers, Inc. Rohde Brothers, Inc. is a leading provider of process piping, HVAC, metal fabrication, industrial controls, and geothermal systems. With a strong focus on technical expertise and collaboration, we are dedicated to building lasting relationships with our clients and partners. Our extensive engineering expertise and comprehensive project capabilities ensure that we deliver cost-effective and efficient solutions to our industrial and commercial clients.

For more information, please contact: Claudia Krepsky

Title: Human Resources Manager

Email: Krepskyc@rohdebros.com